When a business ships packages, its predicted costing doesn't match that of a logistics company. This is mainly because transport and logistics companies use volumetric weight to calculate the shipping price rather than actual weight.

So, let's learn more in detail what volumetric weight is and how to calculate it with examples.

What is Volumetric Weight?

Volumetric weight, also called dimensional weight, is a means of calculating how much a package takes up volume in a container based on its dimensions, not just its weight.

They are mainly used by transportation and shipping companies when lightweight packages are bulky and eat up valuable cargo space.

The Volumetric Weight Formula

Volumetric weights can easily be calculated by multiplying the dimensions, i.e., length, width, and height of the package.

Basic Formula:

Volumetric Weight (kg) = Length × Width × Height ÷ 6000;

where,

- Length, width, and height are in centimeters (cm) or inches

- 6000 is the standard divisor for most carriers

Step-By-Step: How to Calculate Volumetric Weight

Most of the local and international shipments need dimensions in cm, but some domestic shippers use inches too.

Step 1: Calculating Cubic Volume

Formula: Cubic Volume = Length × Width × Height

Example package dimensions:

- Length: 50 cm

- Width: 40 cm

- Height: 30 cm

Cubic Volume= 50 cm × 40 cm × 30 cm = 60,000 cm3

Step 2: Applying the Volumetric Divisor

The divisor determines the final weight used for pricing. Please note, different carriers have different divisors, so always check.

Final Volumetric Weight = Cubic Volume ÷ Divisor

Common divisors:

- Air freight: 6,000

- Express courier: 5,000

- Rail freight: 4000

- Sea freight: 1,000 (or 1,000,000 m3)

Example: using air freight divisors

Volumetric weight = 60,000 ÷ 6,000 = 10 kg

The transportation company will charge you based on whichever value is higher: actual weight or volumetric weight.

Why Volumetric Weight Matters

The following are the main reasons why Volumetric weight matters to both business and transport service providers:

- Cost: Volumetric weight becomes a standard for LTL freight shipping companies to calculate shipping charges. So, if you've got a light but oversized box, your shipping cost will be higher.

- Space Efficiency in Transport: It lets you decide the carrier's price-to-volume ratio for better management of space by package dimensions, not just by weight.

- Fair pricing system: Without volumetric weight, business and logistics companies can negotiate over a fair price without losing money on big, light, and heavy packages.

- International shipping requirements: Most global logistics carriers have adopted volumetric weight along with actual weight as a standard for price calculation.

- Packaging Optimization: Volumetric weight pushes shippers to pack as small as possible, especially in bulk. So, this not only makes the box smaller but also lowers the bill.

- Budget Planning: Anyone can roughly estimate their shipping cost by using the volumetric weight formula and get a realistic shipping budget.

When Volumetric Weight Becomes More Important Than Actual Weight

In most cases, the logistics and transportation company picks whichever is higher: Actual weight or volumetric weight. For example, if your package is big but lightweight, then volumetric weight is preferred.

Thus, it mainly includes low-density items such as:

- Pillows and cushions

- Empty plastic boxes or containers

- Foam products

- Clothing items

- Electronics with oversized packaging

Volumetric Weight Across Different Carriers

How do AAJ Swift, DHL, FedEx, and Blue Dart calculate volumetric weight?

1. Volumetric Weight for AAJ Swift:

- For Domestic B2B shipments: 4500 as the divisor

- For Domestic B2C shipments: 5000 as the divisor

2. Volumetric Weight for DHL:

- For Domestic shipments: 5000 as the divisor

- For International shipments: 6000 as divisor

3. FedEx Volumetric Weight Formula:

- Domestic: 5000 divisor

- International: 6000 divisor

Note: For domestic shipments in inches, FedEx uses 139 cubic inches per pound, which is about 5000 metric.

4. Blue Dart:

- Domestic: 5000 divisor

- International: 6000 divisor

Note: BlueDart rounds to the nearest centimeter and always compares volumetric and actual weight.

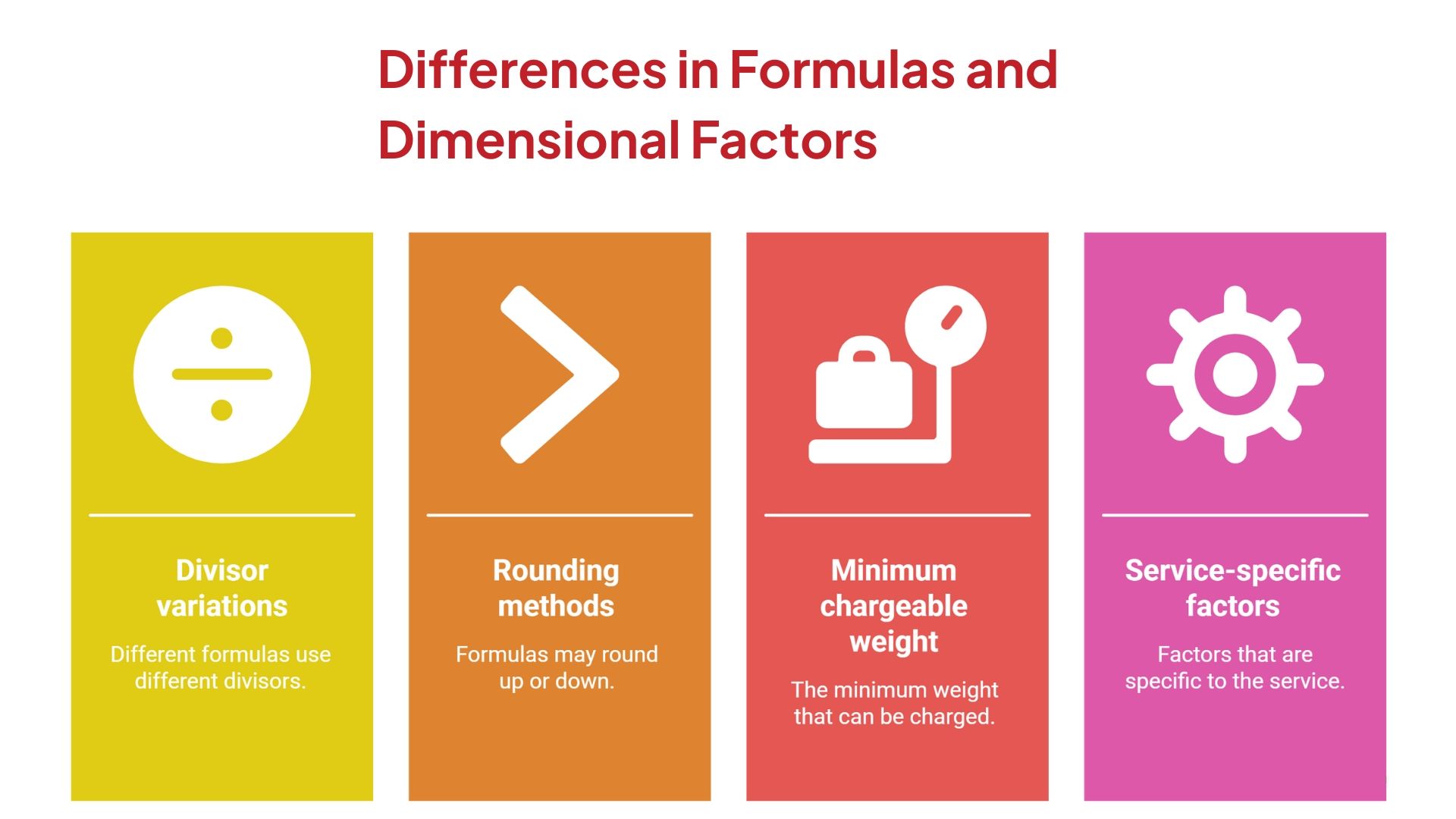

4 Minor Differences in Formulas and Dimensional Factors

These are four minor differences:

- Divisor variations: Most use 5000 for domestic and 6000 for internationals, but some logistic companies also go as low as 4500 for road and premium PTL Transport services.

- Rounding methods: Some round each dimension, while some round the total volume at the end.

- Minimum chargeable weight: Different among most of the logistics companies. For example, DHL starts at 0.5 kg, FedEx at 1 kg, and Blue Dart usually sticks to 0.5 kg for domestic shipments.

- Service-specific factors: Services such as express deliveries often use a lower divisor, making them pricier for light, bulky stuff.

Tools and calculators provided by logistics companies

The following is a list of some transport companies that provide volumetric weight calculators:

- AAJ Swift Volumetric Calculator

- DHL's Online Calculator

- FedEx Rate Tools

- Blue Dart Domestic Shipment Calculator

- Shiprocket Volumetric Calculator

- Chargeable & Volumetric Weight Calculator

4 Best Practices for Managing Volumetric Weight

Companies can cut shipping costs by measuring right, packing smarter, and using tech to avoid mistakes.

1. Train Teams to Measure and Enter Correct Dimensions

Staff training is key. If your team can't measure properly, your shipping costs will be all over the place.

Measurement Training Pointers:

- Use decent rulers or tapes for length, width, and height

- Measure at the widest spots

- Always round up to the next cm or inch

- For weird shapes, measure the biggest points

2. Use Standard-Sized Boxes Where Possible

Standard boxes mean less wasted space and lower volumetric weight.

Box Size Strategy: Pick 5–8 box sizes that fit most products. It simplifies packing and reduces inventory headaches. Common box standard sizes:

- Small: 6″ x 4″ x 4″

- Medium: 12″ x 9″ x 6″

- Large: 18″ x 14″ x 8″

- Extra Large: 24″ x 18″ x 12″

3. Reduce Unnecessary Packaging Material

Smarter packing protects your stuff without adding size or weight. For example, bubble wrap is lighter and takes up less space than foam peanuts, but still protects well.

Here are other packaging optimization steps:

- Remove extra product packaging if you can

- For light stuff, use paper instead of bubble wrap

- Choose boxes that closely fit the product

- Skip double-boxing unless you really need it

4. Use Automation Tools for Weight and Size Capture

Automated systems eliminate the guesswork by measuring and weighing packages exactly and effectively every time. This includes:

- Dimensioning Systems: Cameras and sensors do the measuring.

- Barcode scanners paired with measurement tools cut data entry mistakes.