Many businesses use the words logistics and transportation in the same way, as they are the same. But they have different meanings.

Logistics is a combination of activities, including planning, storing, and coordinating the entire flow of goods. At the same time, transportation is just moving goods from one place to another.

This is the simple difference between logistics and transportation. Let's talk more about how both work together and save your money by choosing the best for your business.

What Is Logistics?

Logistics is a way by which a company plans, organize, and manages the inventory from picking up from businesses and delivering it to end customers. A company that does business in these terms is called a logistics company.

The whole process starts when a company gets an order. This also includes demand forecasting and order management.

So, the next big thing for a company is to decide how much inventory they want to buy in advance, and when to order it for storing and warehousing.

Warehouse companies then update stock levels in their Warehouse Management System (WMS), which helps in tracking and organizing storage space.

Lastly, logistics also deals with tons of paperwork and documentation, including:

- Export packaging and labeling

- Customs clearance forms

- Inspection certificates

- Shipping notices

From order receiving to final delivery, accurate info and timings matter every time. So, data management by WMS and real-time shipment tracking make work more efficient and transparent.

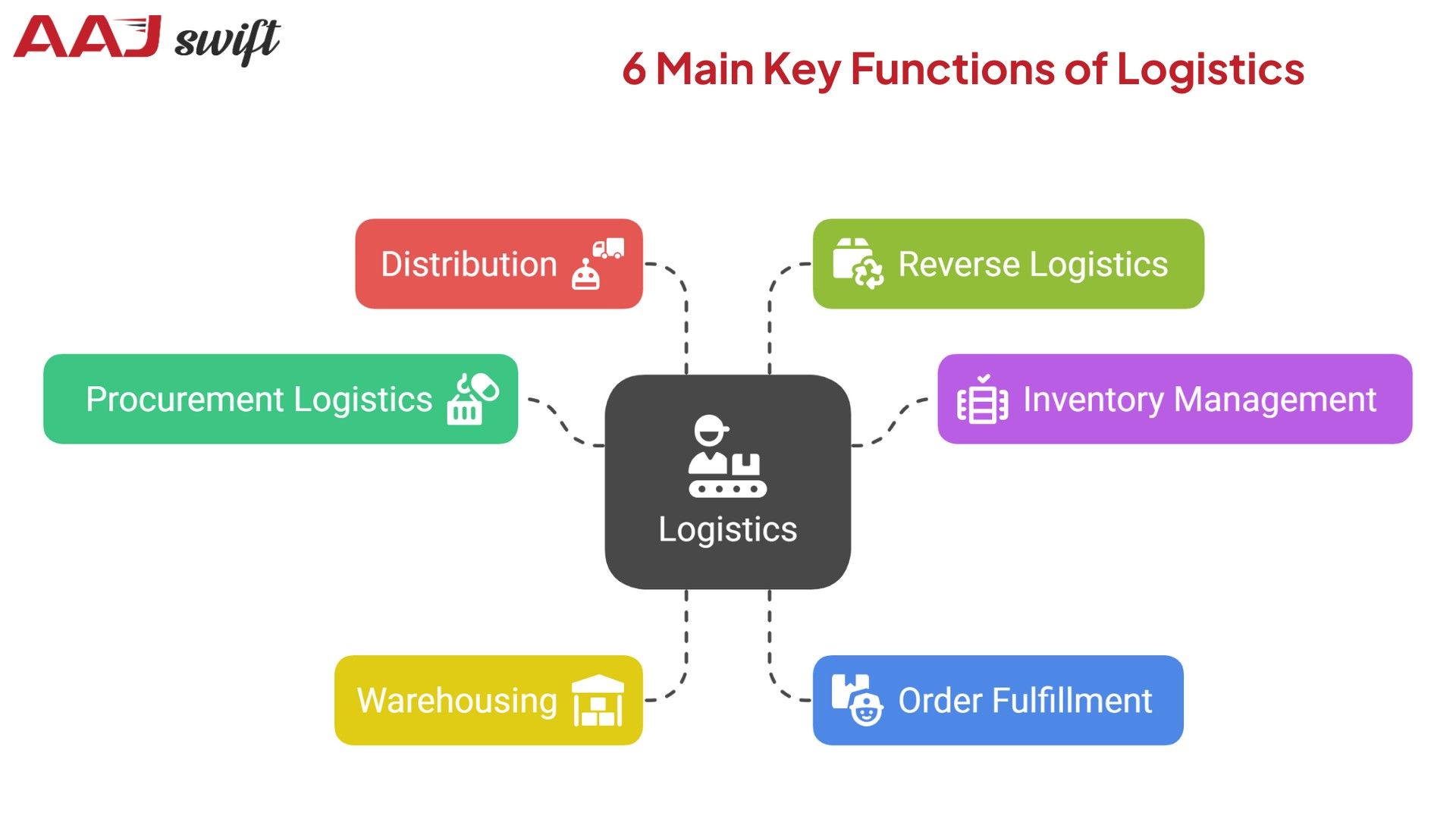

6 Main Key Functions of Logistics

Logistics functions can be divided into six main categories during the entire process from suppliers to customers.

- Procurement Logistics

- Inventory Management

- Warehousing

- Order Fulfillment

- Distribution

- Reverse Logistics

1. Procurement Logistics

Procurement logistics simply means moving raw materials and components from suppliers to production facilities. This includes three main operations:

- Supplier coordination: Can be considered as the foundation of procurement logistics, as the shipping team has to check the supplier performance and negotiate delivery terms with a real logistics company.

- Transport Schedules: Logistic managers select the preferred carrier and optimise shipping routes to match the supplier's delivery time.

- Receiving Operations: This includes checking material quality as per their standards, updating the inventory, and flags any problems to the supplier.

2. Inventory Management

The main goal of inventory management is to keep stock levels checked based on demand and future needs. It includes tracking product quantities, location, and movement through the supply chain.

When to buy more stocks based on demand forecasting, stock replenishment systems, and ABC analysis.

- Demand forecasting predicts future sales to set the right stock levels.

- Stock replenishment systems reorder products automatically when they hit certain low levels.

- ABC analysis sorts inventory by value and importance.

3. Warehousing

Warehousing deals with storing and handling inventory before shipping. The modern warehousing system uses the WMS to pick zones to store incoming inventory and boost efficiency. Warehousing Operations included in this phase are:

- Storage systems: For organizing products based on racking systems, automation, and location tracking.

- Receiving operations: Process incoming shipments for stacking, checking for any damages, and then updating the inventory values.

- Order picking: Picks items for customer shipments and includes methods like zone picking and batch picking.

- Packing and labelling: Make products ready to ship with the right paperwork and shipment details.

4. Order Fulfillment

Order fulfillment is a function that handles customer orders from the point at which they place orders to final delivery. The main goal of this part of logistics is to give a permissible delivery time and keep customers happy.

This starts with order processing, where initial checks are performed for customer details, available stocks, and finally creating picking instructions.

Modern transport companies such as AAJ Swift have built their own automation that speeds things up and cuts down mistakes and delivery time.

Based on details, pick and pack operations are carried out, and a final check is made on items for their packing and whether it is in good shape or not.

On top of it, commercial shipping coordination is set up, i.e., from selecting pickup carriers to adding real-time updates to the customer portal.

5. Distribution

This section is responsible for moving the products out to customers using different channels and serving last-mile deliveries.

This can be done by:

- Transportation planning finds the best routes and carriers.

- Hub and regional networks that bundle shipments to cut transportation costs.

- Last-mile delivery covers the final door-to-door delivery to the customer.

6. Reverse Logistics

Reverse Logistics deals with products that are marked for returns, repairs, or products that are in the end-of-life category.

The goal here is to squeeze out every value without making customers unhappy. Main activities involved are:

- Check returned products and decide whether they should be restocked, recycled, or dumped.

- Refurbished or recyclable products are then packed to be sent back to the factory.

- Disposable end-of-life products.

Importance Of Logistics and Transportation In Businesses

The following are the reasons why there is a need for Logistics in any business:

1. Costs: Highly reduces the expenses by optimizing routes and inventory.

2. Customer Satisfaction: Optimize to ensure on-time and undamaged deliveries that elevate customer trust.

3. Global Expansion: Give a route to source and sell goods in the world's market with an extensive network of logistics companies.

4. Competitive Advantage: Provides a lower price and faster delivery as compared to building your own transportation system.

5. Scalability: Can handle demand spikes effectively and becomes effective, especially in peak season sales.

How Logistics Is Different From Transportation: Comparison Table

The Future Of Logistics And Transportation

Transportation is a part of the services that a logistics company offers. With new trends and tech innovations, logistics companies are also changing their approaches.

The most observable change is the adoption of greenhouse gas-free vehicles such as EVs.

Another change is the dependency on buying tons of new trucks or warehouses. Instead, logistics companies are building and using networks more smartly. They now pool resources, share capacities, and team up with other companies for shared profits.

Here are some key trends that are shaping the future:

- Electric and autonomous vehicles

- Shared transportation networks

- Real-time tracking systems

- Crowdsourced delivery options

- Smart warehouses

Bottom line? Both logistics and transportation are connected, but not the same. Each one has its own job and role in getting goods through the supply chain.