Reverse Logistics: Meaning, Process, Examples, and Why It Matters in Modern Supply Chains

February 11, 2026

AAJ Swift

Reverse logistics refers to the process of moving goods back through the supply chain after they have been delivered to the customer. This includes product returns, repairs, replacements, recycling, and disposal. Unlike forward logistics, which focuses on delivering products to customers, reverse logistics focuses on what happens when products are returned.

With the rapid growth of ecommerce and higher return rates, reverse logistics has become an important part of modern supply chain management. This guide explains the meaning of reverse logistics in simple terms, how the process works in real business scenarios, and why companies need to manage it carefully to control costs, maintain customer satisfaction, and recover value from returned inventory.

What Is Reverse Logistics?

Reverse logistics is the entire journey of the product travelling backwards. It manages the entire re-transportation flows: from picking goods from customers to the logistics system, and finally back to the seller/manufacturer.

Forward logistics involves moving goods to the customer at a specified delivery speed. On the other hand, the reverse logistics network activates the moment a customer hands a return package to a pickup agent. It handles the messy work of returns, repairs, recycling, and disposal.

Reverse Logistics Meaning in Simple Terms

In simpler terms,

- Reverse: Backwards.

- Logistics: Moving stuff.

It literally means the backward flow of inventory.

So, it’s simply the process of handling everything that flows from the buyer back to the seller. Whether it’s a shirt that didn’t fit or a broken phone, you have to bring it back, check it, and decide what to do with it.

In India, where return rates in the e-commerce fashion category can reach 30%, this isn’t just a side operation. It’s the difference between making a profit and bleeding cash for most sellers.

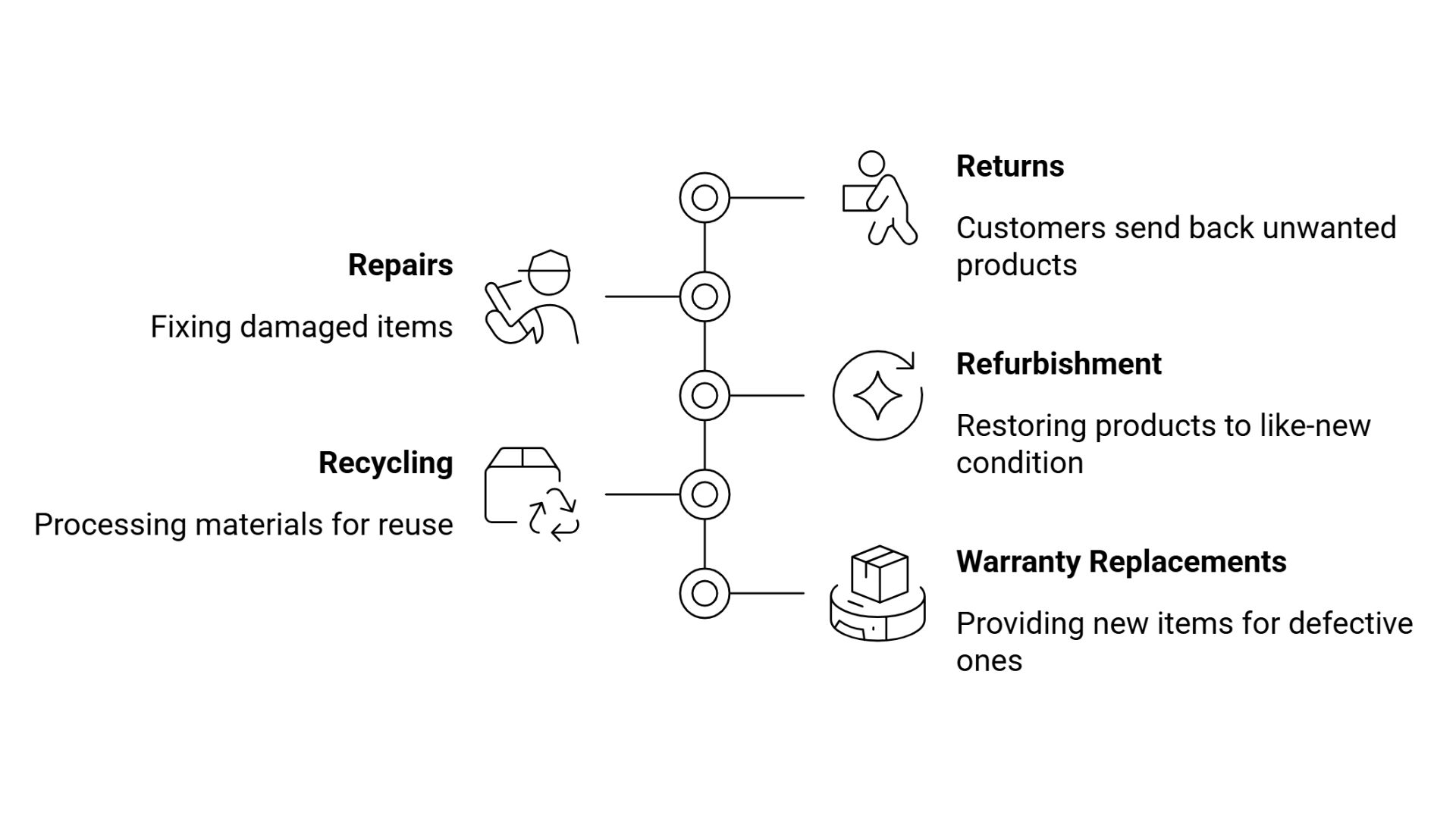

What Activities Are Included in Reverse Logistics?

The following are the main activities that are included in reverse logistics:

- Returns: For example, you placed a return request on e-commerce about the shirt that you received in the wrong colour.

- Repairs: Your laptop screen flickers within the warranty period. You don’t want a refund, but want it fixed. The logistics of getting that device to a service center in Bangalore from your home are the reverse logistics.

- Refurbishment: You might have seen those “Unboxed” or “Grade A Refurbished” phones on Amazon or Cashify? The returned phone is checked, repaired (mostly by replacing the battery and screen), and then put back on the market for resale.

- Recycling: You exchange a used washer for a new one. What will e-commerce do with that? They usually strip for copper and plastic.

- Warranty Replacements: In cases when electronic products are dead on arrival. The company sends a replacement and sends the dead product to the service center.

How the Reverse Logistics Process Works?

Here is the step-by-step guide on how reverse logistics works in the real world:

1. Customer Initiates: It starts when you, as a customer, log into the app and hit the “Return” button. From your side, it’s done, but for the supply chain, the headache has just begun.

2. Reverse Journey: A courier, usually a local partner like Delhivery or Shadowfax, comes to your door for pickup. The agent collects the item, scans it, and brings it back to the local hub with other return orders.

3. Inspection and Decision: When that box hits the warehouse, it doesn’t go back on the shelf. An authorized person then opens it and inspects the problems.

- Restock: It’s fine. Put it back.

- Repair: It’s broken, but fixable.

- Recycle: It’s scrap.

4. Final Outcome: Based on the decision, the items get a new destination. It either goes back to live inventory for restocking, or is shipped to a technician for fixing, or it is sent off to a scrapyard for recycling.

Reverse Logistics vs Forward Logistics

Here is a quick comparison table between reverse and forward logistics:

Why Reverse Logistics Is Important for Businesses?

Reverse Logistics is not only about being nice to your customers, but also more than that. Here are some reasons:

- Stop Bleeding Cash: If you just trash your returned item, you lose 100% of its cost. But if you refurbish it and resell it (like on Amazon Renewed), you recover 50-70 % of that value.

- Customer Trust is Everything: If your return policy is a nightmare, your customer won’t buy from you again. A smooth reverse process makes people feel safe enough to buy more.

- Environmental Factors: If the brand takes back old products and recycles them responsibly, it looks good. Moreover, a brand that responsibly recycles old gear looks a lot better than one that dumps e-waste.

- Unfiltered Feedback: Returns are a brutal reality check and tell you exactly why a product failed. This data is important for helping you fix manufacturing defects.

- Clearing Dead Stock: You don’t want dead stock taking up expensive shelf space in the warehouse. An efficient reverse logistics system clears the clutter so you have room for products that actually sell.

Common Challenges in Reverse Logistics

If this sounds easy, ask any warehouse manager about their “Returns Bay.” They’ll probably groan.

- The Unpredictability Factor: You know exactly how much you are shipping next week. You have zero clue what it is and how many are coming back.

- The “Hidden” Costs: It costs significantly more to process a return than to ship a new order. You have the pickup cost, the inspection labour, and the repackaging. Moreover, sometimes it costs more to process a return than the item’s worth.

- Quality Control is Subjective: For example, a scratch on the fridge door. One inspector might say sell it; another might say scrap it. Lack of standardization kills efficiency.

- Re-Packaging: New products come in perfect, sealed original boxes. Returns often come back in torn and taped-up boxes. Repacking and fixing those boxes took a lot of time and labour.

- Value Drops Fast: Electronics usually lose value every single day. A smartphone returned today is worth less next week. If your reverse process is slow, that “new” phone becomes “old” stock before you can even resell it at a good price.

- Fake Returns: Tons of unethical customers do these. One of the most common examples is clothing. They usually wear dresses and then return them. Or worse, someone swaps genuine delivered products with fake ones and raises return requests.

- Operational Complexity: Forward logistics is automated, while reverse logistics is manual. You aren’t moving clean pallets; you are handling one open box at a time. It requires a real person to inspect every single box, which costs you time and money.

Conclusion

Reverse logistics isn’t just about returning your order. It is the backbone of a modern brand. It’s the difference between a one-time buyer and a loyal customer.

As e-commerce in India keeps exploding, the companies that master this reverse flow are the ones that will win and make profits.

But this all comes with a cost, i.e., managing returns is messy, expensive, and eats up your time. So, building a reverse supply chain is a must.

At AAJ Swift, we handle the headache of both forward and return orders so you can focus on your business. We also have warehouses where you can stock your returns for faster deliveries.

So, get a quote today, and let’s turn your reverse logistics into a competitive advantage.