There is a new trend among modern customers, i.e., they want their deliveries faster and on time. This creates a need for transport companies to catch up with this trend. As a fact, about half of customers (~55%) will happily switch to a competitor if they provide much faster delivery.

This kind of pressure has made businesses (especially e-commerce) make multiple regional warehouses to deliver faster to a specific region with a dedicated delivery zone.

So, a delivery zone is a way by which a company splits up a city into smaller regions to make smoother, faster, and cheaper last-mile logistics.

When a company decides its delivery zones, it makes delivery faster with a happy customer. But there are lots of questions that are still unanswered, such as how it works. What are the methods and their types? That's what you all learn in the following article.

What Is a Delivery Zone?

A delivery zone is basically a mapped-out area used by a company to plan deliverable areas and possible costs. They split up their transportation service area into these bite-sized zones to plan routes, assign delivery staff, and set prices.

In other words, it is all about grouping areas by how far they are, and it somewhat helps businesses to sort out their shipping.

Based on shipping requirements, the delivery zone varies, such as:

In eCommerce, businesses use zones to set different courier charges and timelines based on the product's shipping site.

Similarly, courier networks also use zones, but their delivery zones have larger serviceable areas. For example, Southwest Delhi, the entire Delhi, or even India could be a delivery zone for a courier network that ships goods from the USA.

In these cases, Third-party logistics (3PL) providers come in handy. They act as a link by getting bulk shipments from a courier network and distributing them into their own networks.

It includes shipping to multiple warehouses based on the customer's pin codes, and then creating workable zones to cut down shipping costs for clients, and at the same time, faster deliveries.

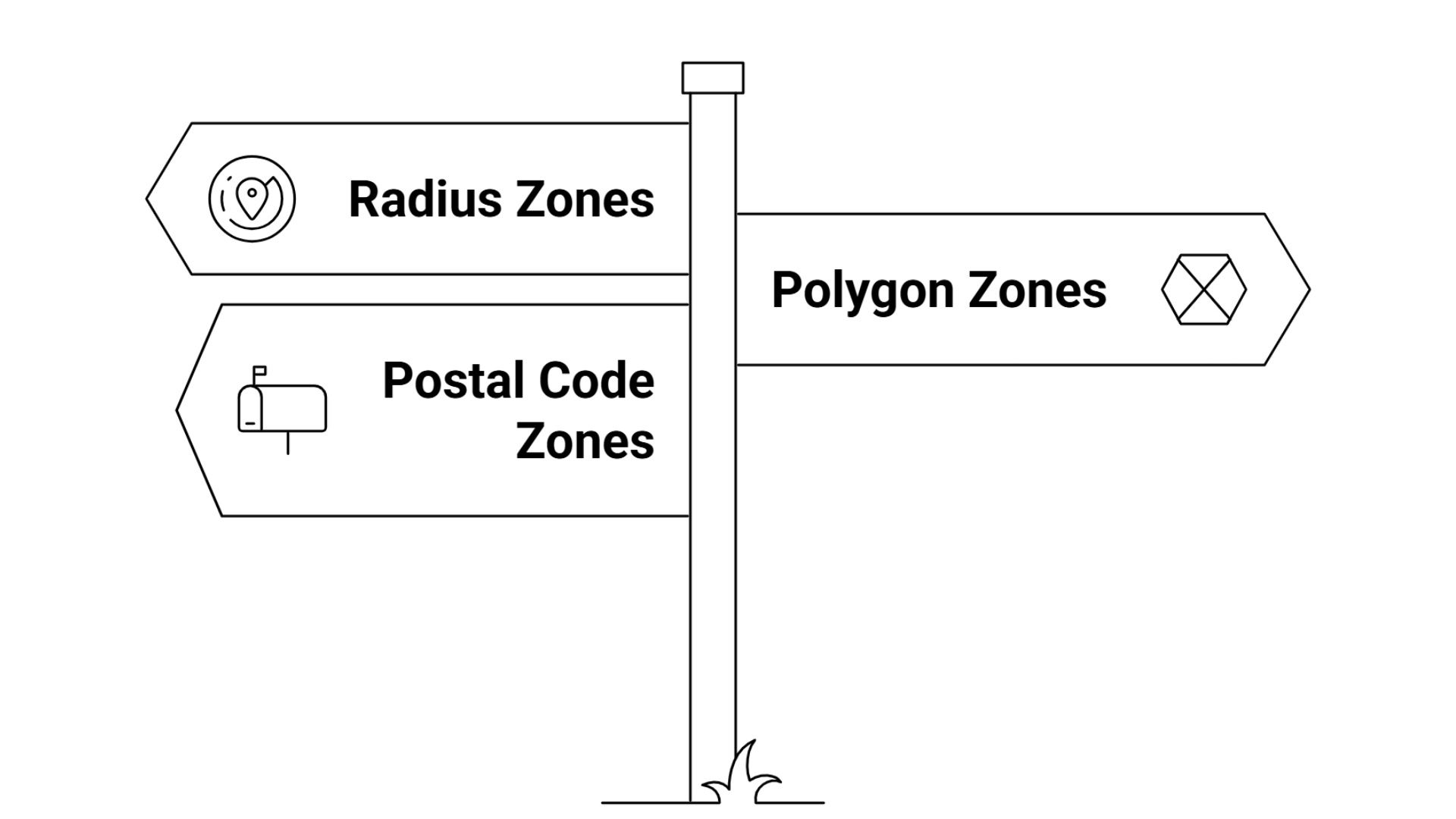

Delivery Zones Methods: Radius, Polygon, and Postal

Companies mainly use three main delivery zones that are governed by distances, natural boundaries, or postal codes.

1. Radius / Ring Zones (Km/Miles)

Radius zones are the classic method and are the simplest (on paper). You just need to draw circles around the logistics hub. Circles that are close to the warehouse have cheaper and faster delivery as compared to the farthest ones.

Example: The first ring covers 0-5 km, 2nd one covers 5-15 km, and 3rd, the last one, covers 15 to 30 km from the center of the warehouse.

As it is the simplest delivery zone method, it offers:

- Super straightforward for both businesses and customers

- Quick to calculate shipping costs

- Works best if you've got one main hub.

Limitation: Simpler it looks, but there is a catch. Real life and roads aren't perfect circles. So, a customer within 5 km but across a jam-packed bridge might make delivery longer than someone who is sitting 10 km away on a smoother highway.

2. Polygon / Custom Shape Zones (City Districts)

Polygon zones are mapped based on the real neighborhoods or district areas. This serves the purpose by preventing bad serviceable regions such as rivers, highways, or high-traffic areas. Big B2B logistics companies adopt this delivery zone model.

Advantages:

- City neighborhoods or districts

- Areas split by highways or rivers

- Places with similar population density

- Business areas vs. residential ones.

Limitation: Polygon zones require extensive planning and more homework. You'll have to study maps and maybe even sit in traffic to figure out what makes sense.

3. Postal/Pin-Code Based Zones (Common In India)

In India, pin code-based zones are king. You just group deliveries by pin code, which makes them easy to sort, easy to plan, and the postal system already has the groundwork laid out.

Here's how it often goes:

- Zone A: Major metros like Mumbai, Delhi, Bangalore

- Zone B: State capitals and big cities

- Zone C: Smaller cities and district HQs

- Zone D: Rural and remote spots.

Limitation: With wrong data, such as an incorrect pin code? Your parcel could end up somewhere else.

3 Main Purposes of Creating Delivery Zones

There are three main reasons for creating delivery zones. These are timing, cost, and pricing.

1. Manage Delivery Timeline Effectively

Zones help companies to set realistic delivery windows for each area. Moreover, grouping deliveries by zone means:

- Fewer missed deliveries

- More accurate ETAs for customers

- Better route planning

- Scalable

For example during Diwali sales, logistics can split up busy zones to handle the flood of orders.

2. Balance Operational Cost Vs. Service Level

Each zone has its own advantages based on traffic, distance, and delivery times. Based on metrics, a B2B transport service provider can decide where they have to focus their energy more, such as:

- Fuel spend per zone

- Driver overtime by area

- Complaint rates

- How often do deliveries need a second attempt?

Example: City/Urban zones might mean more stops but also more jams as compared to rural zones.

3. Enable Dynamic Pricing And Fuel Optimization

Companies monitor fuel consumption and drive time per zone, which can help to adjust pricing as per demand. Some dynamic pricing factors are:

- Fees based on distance

- Fuel surcharges for the really remote places

- Peak-hour pricing.

Types Of Delivery Zones In Logistics

Logistics companies sort delivery zones by distance and geography. Here is the whole list:

Table

Why Delivery Zones Matter In Logistics Planning

Delivery zones are a game-changer for transport and logistics because of the following reasons:

- Cost Control Benefits: It helps companies to cut shipping costs and make more profits on each order. This can be done by:

- Grouping nearby deliveries to save on last-mile costs

- Reduce fuel bills with shorter drives

- Lower maintenance costs for vehicles

- Route Efficiency: A smart zone means better delivery route optimization, which simply means drivers have to spend less time on the road and in traffic.

- Customer Service: Most logistics companies, like AAJ Swift, update users that their package has been received at the nearest hub/zone. So, they know when to expect their stuff.

- Better Planning and Resourcing: Companies use delivery zone data to decide where to put new warehouses or which areas need better coverage.

- Pricing Made Simple: Zones create a region to serve based on the distance from the central hub. So, closer zones offer cheaper pricing.

- Growth Planning: Companies can use zone data to predict the next target area that helps them expand markets to new regions.

Factors To Consider When Defining Delivery Zones

Setting up a boundary or a circle on a map doesn't create an efficient delivery zone. Here are some factors you must consider when creating a delivery zone:

- Geographic Layout and Distance: Start with the area's physical layout. While route planning considered distance, rivers, mountains, and highways as considerations.

- Customer Order Patterns: Urban areas or densely populated areas have lots of frequent orders as compared to parts of the city with malls, stations, metros, or airports. So, knowing where your customers sit most is the key.

- Traffic and Transportation: You must take into account road conditions such as peak traffic hours, potholes, and water logs, as well as the transportation options you have.

- Cost Factors: Fuel prices and tolls can be determining factors in defining zone boundaries. Having an expensive toll road might be good to have its own zones.

- Data Analysis: Use delivery data and delivery density numbers to finalize the perfect area for your zone's warehouse.

Common Mistakes To Avoid In Delivery Zone Planning

If you plan your delivery zones and avoid following common mistakes, you not only save your profit margin but also give customers a faster delivery.

1. Ignoring customer demographics: Urban areas, high-end society, and young people are some of the most favorable customers for e-commerce. So, try to map them down closer to the warehouse to serve them fast.

2. Making zones too big: It slows down the delivery and, at the same time, burns more fuel. This makes the whole process inefficient and becomes a headache. And, if the delivery is long and fails, then there is a total loss of fuel too.

3. Not using traffic data: Better switch to lighter vehicles during rush hours, which also tremendously decreases the effect of traffic on delivery time. Some other mistakes you should avoid:

- Check delivery history

- Not considering the busy seasons

- Never adapting to new zones as per demands

4. Not tracking performance: You must track the performance of your delivery times and customer feedback.

5. Making zones too complicated: Simple boundaries based on the city or district serve the best and reduce any confusion among drivers and logistics partners.

6. Not planning for growth: Your zone should be future-proof, especially to handle more orders during sales and peak seasons.

I hope you get a glance at what delivery zones are. You can also partner with us, AAJ Swift, for your zonal delivery excellence. We specialized in zonal warehousing and logistics services with specialized optimization routes and last-mile solutions.