Last Mile Logistics: The Backbone of Modern E-commerce and Supply Chain Success

October 30, 2025

AAJ Swift

India's logistics market already crossed $3 billion in 2024, and many predict it will reach twice that by 2028. This is all possible because of our love for online shopping. But you may not be aware that a significant portion of operational costs is absorbed by last mile logistics services that deliver products to customers' doorsteps.

It is estimated that last-mile logistics can account for up to 50% of total shipping costs. This part of logistics is a key factor in building customers' trust, which increases the likelihood of repeat customers. Similarly, if a company fails on last-mile services, they not only lose trust but also money.

Proper training, route optimization, and behavioral training must be implemented to maintain customer trust. However, there is more to it.

Let's dive deeper into the topic and learn how Last Mile logistics works and how you can overcome major challenges.

What is Last Mile Logistics?

Last mile logistics is also known as the last mile delivery process. It directly moves products from a warehouse (or a distribution center) to the customer's door.

It sounds simple, but it is actually a more complex and expensive part of the logistics process.

The time and distance to the final delivery depend on the nearest operational hub and the efficiency of the delivery routes.

Last mile logistics includes all delivery types, including:

- Home deliveries for online customers

- Store and office business b2b deliveries

- Special and super-fast deliveries

Why does it matter? This final logistics step completely determines how happy your customer is. If delivery is seamless and customers are satisfied, this only means they keep coming back to purchase again.

Example: When you order a phone from Flipkart, it first ships from a distant warehouse to your nearest logistics hub. From there, it is on its last-mile logistics, with a status of "out for delivery," and is later delivered to your address.

Understanding the Complete Delivery Chain

The logistics process has three major parts: first, middle, and last-mile delivery.

First Mile begins once the item departs from its origin. It may be a factory, warehouse, or retailer.

Middle Mile majorly includes moving goods to the final local hub or a micro fulfillment center. Trucks, airplanes, railways, and ships are used to move goods in bulk between cities and even nations.

Last Mile includes picking orders from local hubs and bringing them directly to customers.

Here's a detailed comparison table of the three major parts of the delivery chain:

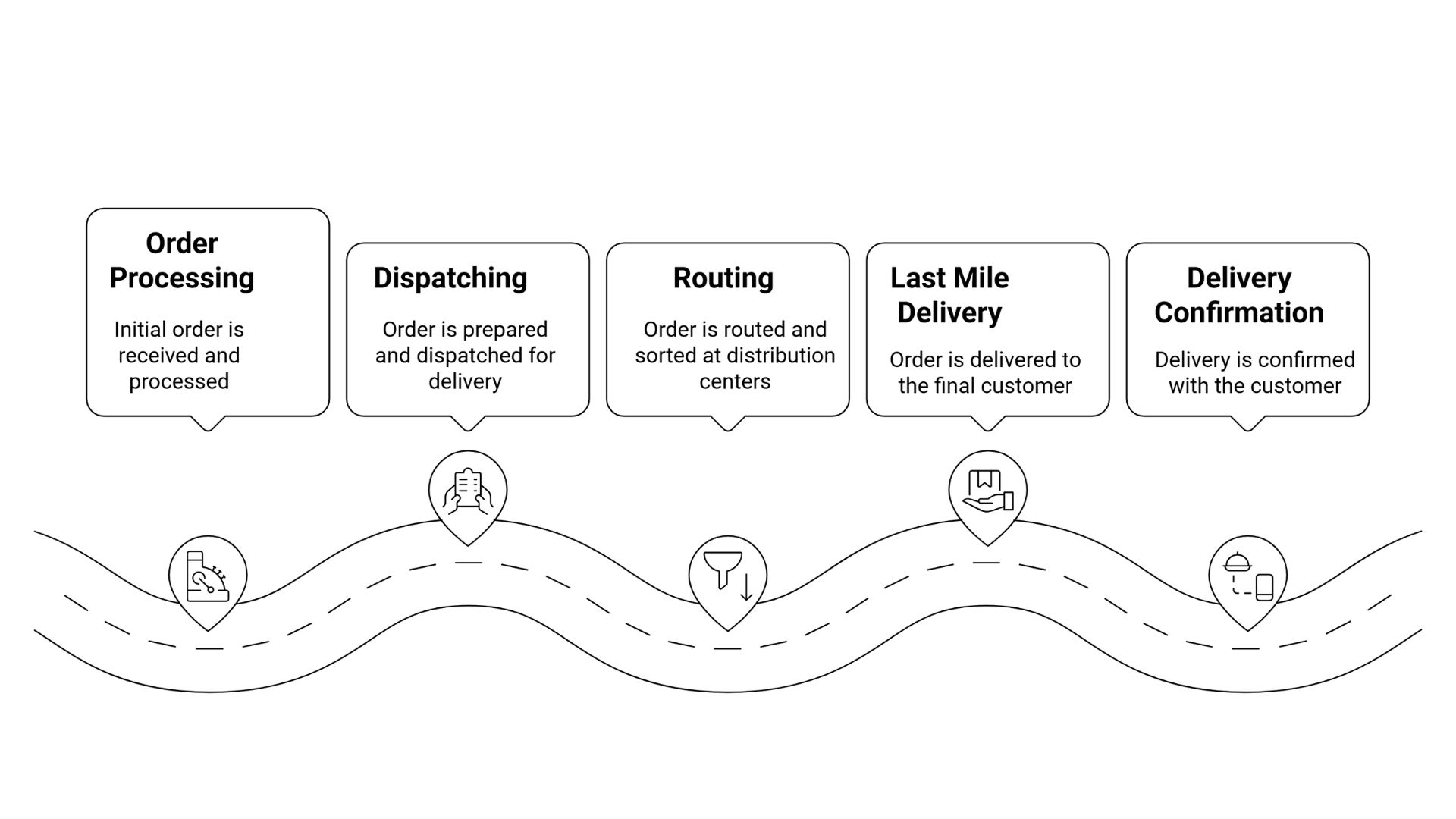

How Does Last Mile Logistics Work?

There are multiple steps in last-mile logistics, and each of them is needed to run logistics smoothly.

Step 1: Order Processing

It starts as soon as the customer places an order. A WMS or order management system first checks and reconfirms its availability and storage location. Workers pick up your items from the storage shelves, pack them, and place a unique shipping tag with your address and tracking number.

Step 2: Dispatching

It can be either a full truckload (FTL) or part load transport (PTL). Packed orders are sent to the warehouse for sorting and consolidation.

Step 3: Routing and Sorting Centers

Here, packages are consolidated with other items bound for the same route. The packages are then loaded on trucks or other modes of transport and finally sent to local delivery hubs.

Step 4: Last Mile Delivery

The package is marked as "out for delivery" and leaves the final hub, and finally reaches the customer's doorstep.

Step 5: Delivery Confirmation

The delivery agent scans the package's barcode at the customer's door, asks for remarks or signature as proof, and marks the order "Delivered."

Key Challenges In Last Mile Logistics

The following are some of the main issues and challenges in last-mile logistics:

- High operational costs: The last mile accounts for 50% of total shipping costs.

- Consumer expectations: Customers have options such as same-day and next-day delivery, flexible scheduling, and even delivery on holidays.

- Failed delivery: If no one's at home, delivery agents have to make another attempt, which is a waste of time and money.

- Return logistics: More online shopping means more returns, and handling those quickly is tough and resource-intensive.

- Environmental awareness: The government encourages businesses to adopt cleaner, greener modes of transport, especially in big cities. Adopting EVs is a must, but it again requires capital.

- Seasonal spikes: High purchase volume during the festive season makes it challenging to handle the additional volume of packages.

- Technology integration: Many companies struggle to integrate new tracking systems and route-planning tools into their old-school setups.

Modern Last Mile Logistics Solutions

To meet the above challenges in last-mile delivery, here are some of the modern solutions:

- Route Optimization: Advanced software guides drivers on how to choose optimal routes to reduce delivery time and fuel.

- Tracking Device: GPS-enabled vehicles allow customers to have real-time updates on their shipments. This also helps drivers to stay on schedule and prevent delivery failures.

- Predictive analytics: Use a data-driven approach to forecast the best possible routes, sales hikes, and best delivery times.

- Adoption of EVs: Electric vehicles are increasingly being adopted for last-mile deliveries, such as electric bikes and vans.

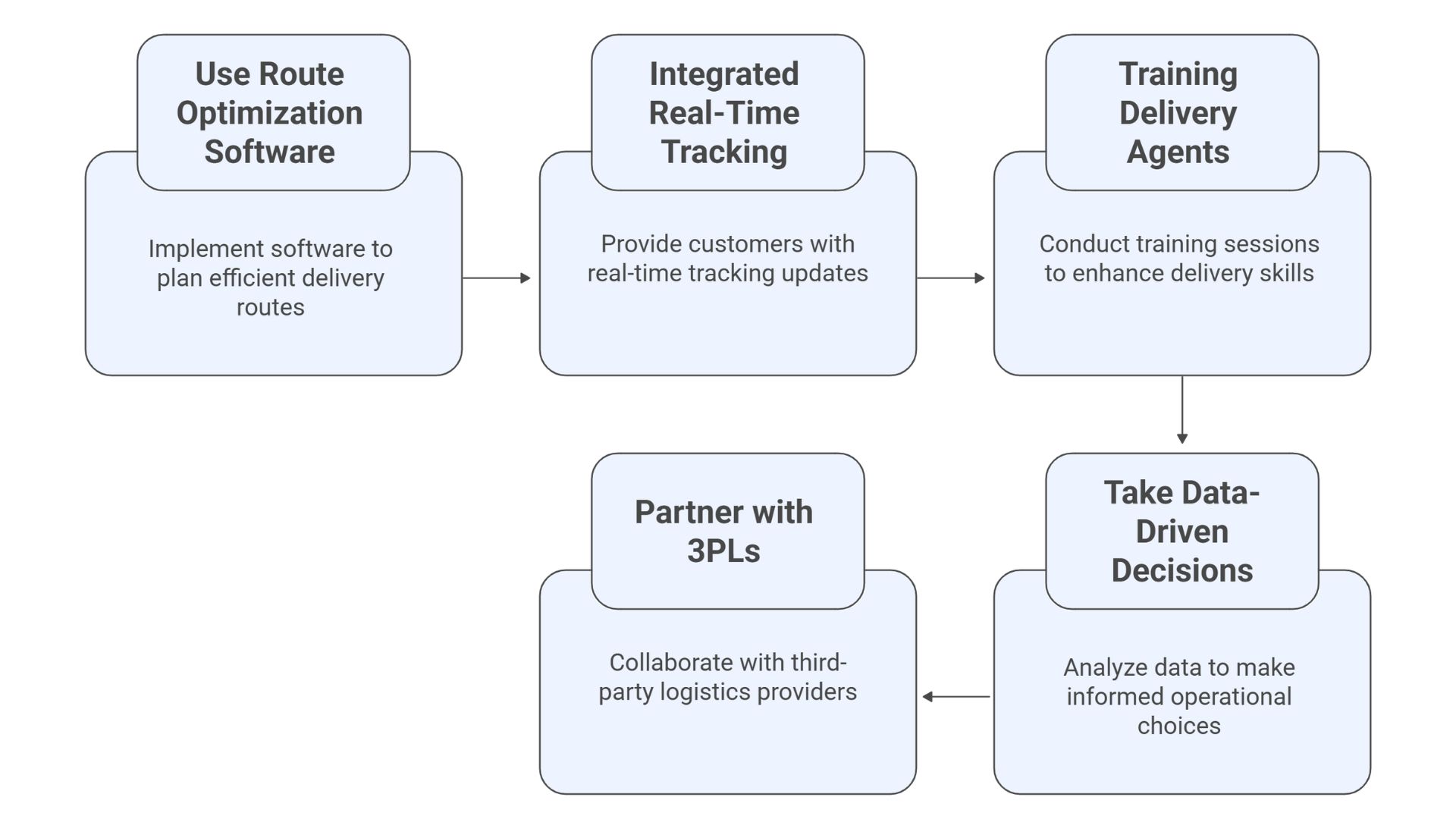

How Businesses Can Improve Their Last Mile Efficiency

The following are five ways to speed up your last mile and save money:

1. Use Route Optimization Software

By planning the most efficient routes based on traffic and vehicle availability, route optimization software can cut fuel costs by 20%.

2. Integrated Real-Time Tracking for Customers

Everyone loves to know where their things are, especially in the last mile. So, businesses should share GPS data for last-mile delivery with their customers.

3. Training Delivery Agents

Transport companies should hire local drivers who know the quick and reliable route. Drivers should be trained to deal with customers.

4. Take Data-Driven Decisions

Track delivery times, fuel efficiency, and customer reaction. Based on these data, adjust your routes, identify the bottleneck operations, and optimize them.

5. Partner with 3PLs

Third-party logistics are known for their flexibility. So, during peak periods, you can share the burden with other 3PL transport service providers without purchasing additional vehicles or drivers.

How To Choose The Right Last Mile Logistics Partner

Picking the best last-mile logistics partner can help you manage the costs by a significant margin.

Here is the table that outlines the key factors that you should look for while choosing a last-mile logistics provider:

Some other questions that you must ask before choosing the one:

- Does it send delivery notifications to customers?

- Can they also handle the return?

- What if a package is lost or damaged?

- Did they provide proof of delivery or a photograph for delivery confirmation?

So, having a reliable last-mile logistics partner is like an extension of your business, especially for modern e-commerce. When it is done right, customers will notice, and profits will go up. If you're looking for a reliable last-mile delivery partner, contact us for a quote today.