Freight Cost Explained: Everything Businesses Need to Know About Shipping Expenses

October 31, 2025

AAJ Swift

Freight expense is one of the determinants that significantly influence a company's supply chain effectiveness and profitability. Be it an eCommerce, manufacturing, or B2B business, effectively managing freight shipping expenses can be its make-or-break. Each product that gets shipped from a supplier to a customer has layers of logistics costs involved that must be effectively evaluated and contained. Let's dive into the freight cost meaning, its main elements, how it is calculated, and real-life ways to minimize it.

What Is Freight Cost?

In plain language, freight cost is the overall amount paid to get products from place to place. It encompasses not only the shipping charge but also additional charges such as fuel, handling, Packaging, and insurance. Freight cost is important to know since it affects product pricing, competitiveness, and profitability directly.

In global shipping, Cost and Freight (CFR) is widely referred to. It refers to the seller's agreement to pay for transporting merchandise to an arrival port, but not the risk after loading onto a ship.

Companies that maintain tight control over freight expenses are able to plan the movement of inventory, budget costs, and establish a clearer b2b logistics strategy.

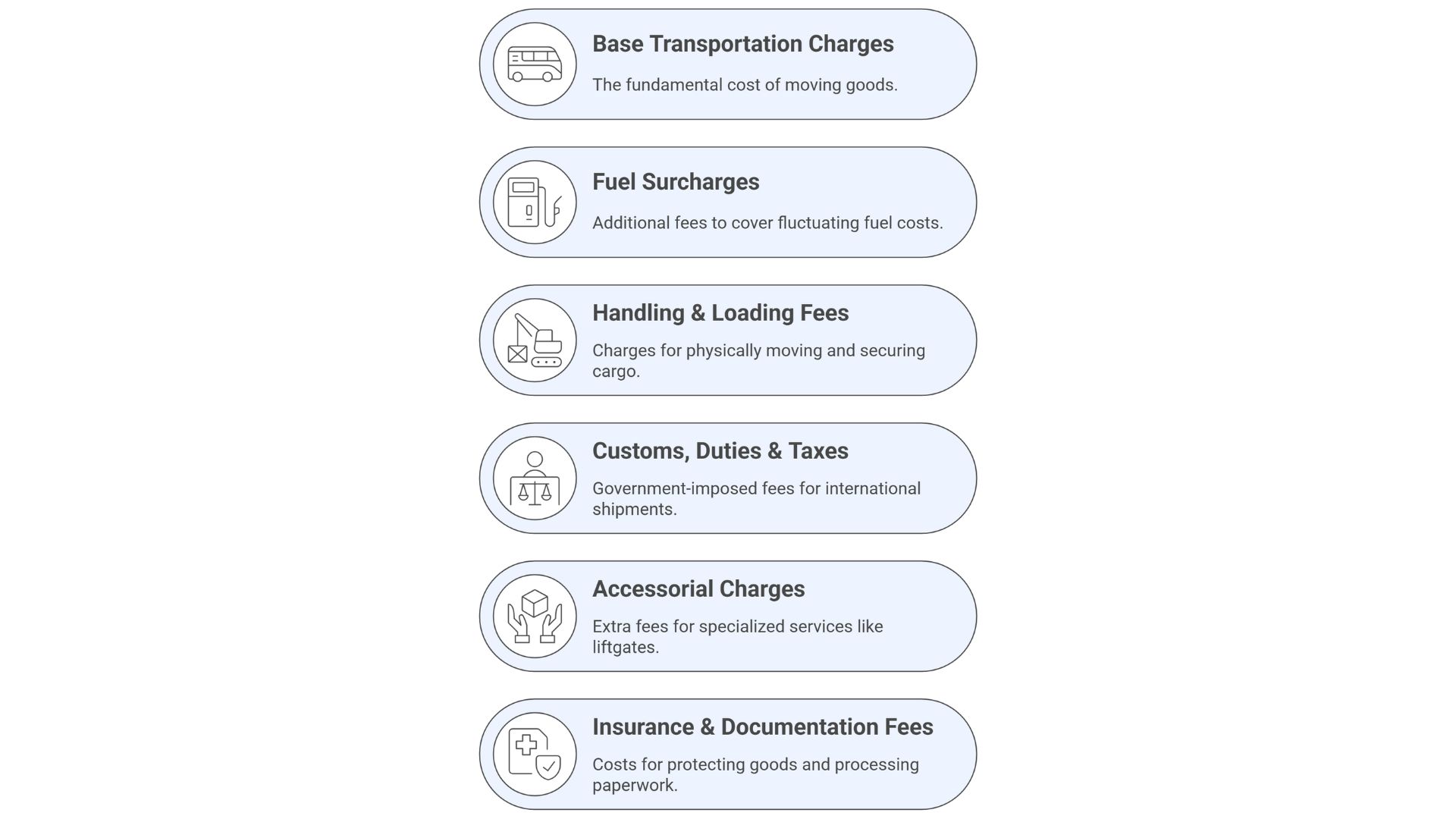

Key Components of Freight Charges

Freight shipping expenses consist of a number of interconnected components. Being aware of these categories enables companies to know where their money is spent.

1. Base Transportation Charges

This is the primary charge for transporting goods between the origin and the destination. This varies depending on the distance of the shipment, transportation mode (air, sea, rail, or road), and carrier choice.

2. Fuel Surcharges

Fuel prices vary often, and surcharges are tacked on by carriers to adjust for the fluctuations. Keeping tabs on fuel trends enables companies to budget and prepare for these extra charges.

3. Handling & Loading Fees

Loading and unloading labor charges are usually accounted for as handling charges. Bulkier items such as heavy machinery or sensitive goods generally have a higher handling cost.

4. Customs, Duties & Taxes

For foreign shipments, import/export taxes, tariffs, and duties are added to the overall freight price. Compliance with documentation and regulations to prevent additional costs is essential.

5. Accessorial Charges

These charges cover extra or specialized transport services like residential delivery, inside pickup, liftgate service, or wait time. Each of these can double or triple the final cost if not controlled effectively.

6. Insurance & Documentation Fees

Insurance protects against loss or damage in transit, and documentation charges are for the preparation of bills of lading, certificates, and customs documents. All these combined protect and validate goods in transit.

How Freight Costs Are Calculated

Calculation of freight cost may be intricate, but knowing the fundamentals is vital in controlling cost.

The formula for the general freight rate calculation is as follows:

Freight Cost = (Base Rate + Fuel Surcharge + Accessorial Charges) × Distance Factor

Many companies employ a Freight Cost Calculator to streamline this task. Online calculators estimate freight shipping costs depending on shipment information and enable firms to compare rates and make economical choices.

Weight-Based Pricing

This pricing method suits heavy freight mostly. Carriers charge according to the actual weight of commodities. It will suit best for solid, dense products.

Volume-Based Pricing

When the space in a container is most important, carriers charge by volume instead of weight. Light but bulky freight belongs to this category.

Dimensional Weight (Volumetric Weight)

In the case of air and courier services, dimensional weight pricing is used. It takes into account size and weight, such that heavy but oversized items are not undervalued. The calculation allows carriers to balance space allocation efficiency.

Factors Affecting Freight Cost

A number of factors determine how much a company finally pays for shipping:

- Distance: Longer distances typically translate into greater expense.

- Mode of Transport: Air transport is quicker but more expensive than sea or land.

- Weight & Volume: Bulky or heavy goods add more to transportation expenditure.

- Type of Goods: Fragile or hazardous goods need to be handled differently.

- Destination Accessibility: Far-flung or inaccessible places might entail accessorial charges.

- Market Conditions: Seasonal demand and carrier availability also influence pricing.

Different Types of Freight Charges

Knowledge of various pricing terminology enables businesses to select the proper trade agreements and shipping conditions.

Prepaid vs Collect Freight

- Prepaid Freight: The transportation is paid by the shipper before dispatch. It's standard when the seller controls logistics.

- Collect Freight: Shipping costs are paid by the receiver (buyer) on delivery. It offers flexibility but slows transactions.

FOB (Free on Board)

With FOB, risk and ownership transfer when goods are loaded onto the shipping vessel. The buyer takes responsibility for shipping and insurance from then on.

CIF (Cost, Insurance, and Freight)

The CIF Incoterm involves the seller paying for goods, insurance, and freight to the port of destination, and the buyer is responsible for unloading, duties, and taxes.

Each contract influences who pays what, and knowing these variations keeps companies away from conflicts or surprise logistics fees.

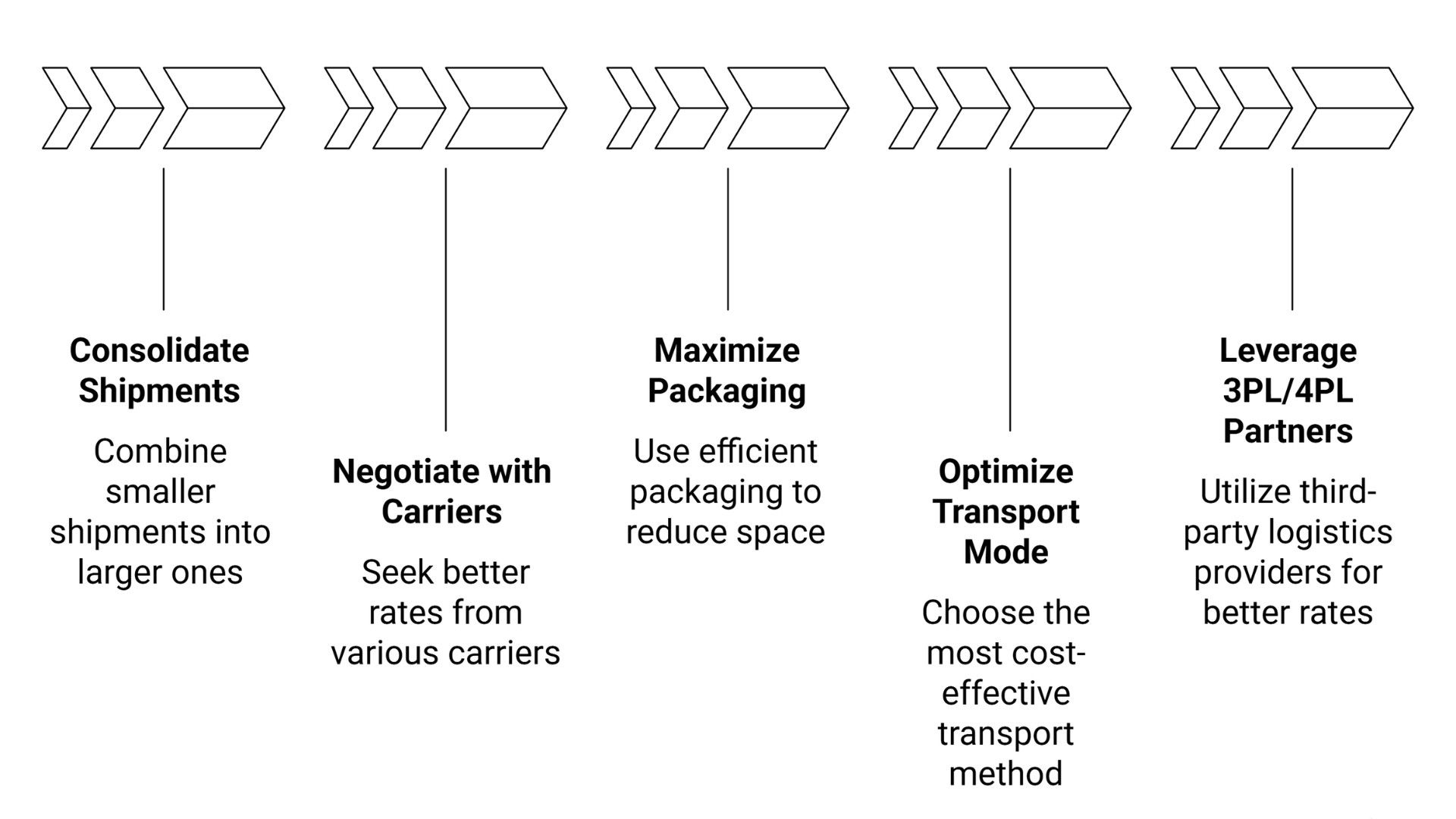

How to Lower Freight Cost - Freight Rate Management

Reducing freight shipping expenses without compromising service quality is a top priority in logistics. Here are successful approaches:

1. Consolidate Shipments

Merging multiple small LTL shipments into one large shipment lowers per-unit expenses. It also maximizes carrier space and reduces handling charges.

2. Negotiate with Multiple Carriers

Establishing relationships with multiple carriers enables companies to shop around and obtain volume discounts. Regular rate checks avoid cost inflation.

3. Maximize Packaging

Packaging design influences space usage and freight class. Utilization of lighter or smaller materials reduces dimensional weight charges and maximizes container capacity.

4. Optimize Mode of Transport

Choosing between road, rail, sea, or air is based on time sensitivity and cost. For instance, sea freight is cost-effective for large loads, whereas air freight is appropriate for express deliveries.

5. Leverage 3PL and 4PL Partners

Third-party logistics (3PL) and fourth-party logistics (4PL) partners oversee shipping operations, usually at reduced costs because of established networks and volume rebates. They can also leverage technology to monitor costs and optimize route planning.

Conclusion

It is important to understand freight cost meaning and the variables behind it for any company that depends on shipping. By examining each of the cost factors and using tools such as a Freight Cost Calculator, businesses can make informed choices that keep freight shipping costs managed and predictable.

Whether negotiating cost and freight contracts or testing flexible shipment alternatives, companies should continually track and negotiate rates. An effectively managed freight policy not only saves unnecessary expense but also increases productivity and customer satisfaction.

Freight expenses will never go away, yet with the right planning strategies, they can become an accepted, open-ended aspect of conducting business in today's supply chain.