How Transport Management Systems (TMS) Are Transforming Modern Logistics

November 25, 2025

AAJ Swift

The Indian logistics industry has grown massively, with an annual growth rate of 15%. However, this success is challenged by rising fuel prices and labor/driver costs. To overcome these challenges, logistics companies develop an automated route-planning system that slashes shipping costs by 20%. This system is called a Transport Management System (TMS).

A Transport Management System manages, organizes, and consolidates goods based on the common routes and delivery points. This system acts as the nerve center of modern supply chains, linking warehousing, regional hubs, trucks, and customers to enable faster and more optimized deliveries.

So, whether you're a small business that ships a few orders weekly or a giant retailer with Part load transport. In both cases, you can take advantage of TMS technology and save about 20% of your total shipping costs.

But, how does it work? What are the steps involved in building a Transport Management System for your company? Finally, why do all modern businesses choose a B2B transport company with a TMS system?

What Is Transport Management?

Transport management is the process of planning, organizing, and controlling the movement of goods from one place to another (or to the final delivery point). It is an invisible glue that connects every part of the supply chain to deliver goods efficiently.

In simpler terms, you can think of transport management as a school principal. Instead of coordinating teachers and students, a transport manager coordinates warehouses, trucks, ships, planes, and trains to deliver faster and more economically.

Role of Transport Management In Supply Chain

As stated earlier, a transport management acts as a bridge that connects every unit in the supply chain island, and here's how it fits in:

- Procurement: Teams up with the business and schedules pickups.

- Warehousing: Plan shipments to avoid warehousing based on expected delivery date and available fleet routes.

- Manufacturing: Ensuring on-time delivery for raw materials and produced goods out for distribution.

- Last-Mile Delivery: Optimizes final delivery routes with real-time customer notifications.

- Returns Management: Efficiently handles product returns and exchanges, then loops back to the supply chain.

- Customer Service: Provides live tracking and delivery updates.

Difference Between Transport Management, Fleet Management, and Logistics Management

What Is A Transport Management System (TMS)?

A Transport Management System is automated software that handles all the work for a B2B logistics company, from planning and managing goods to final delivery. The primary goal is to optimize operations so that other businesses can ship goods faster, at lower rates, and with greater reliability.

Example: Flipkart uses TMS to manage thousands of deliveries every day by choosing the fastest routes and the cheapest carrier for each package.

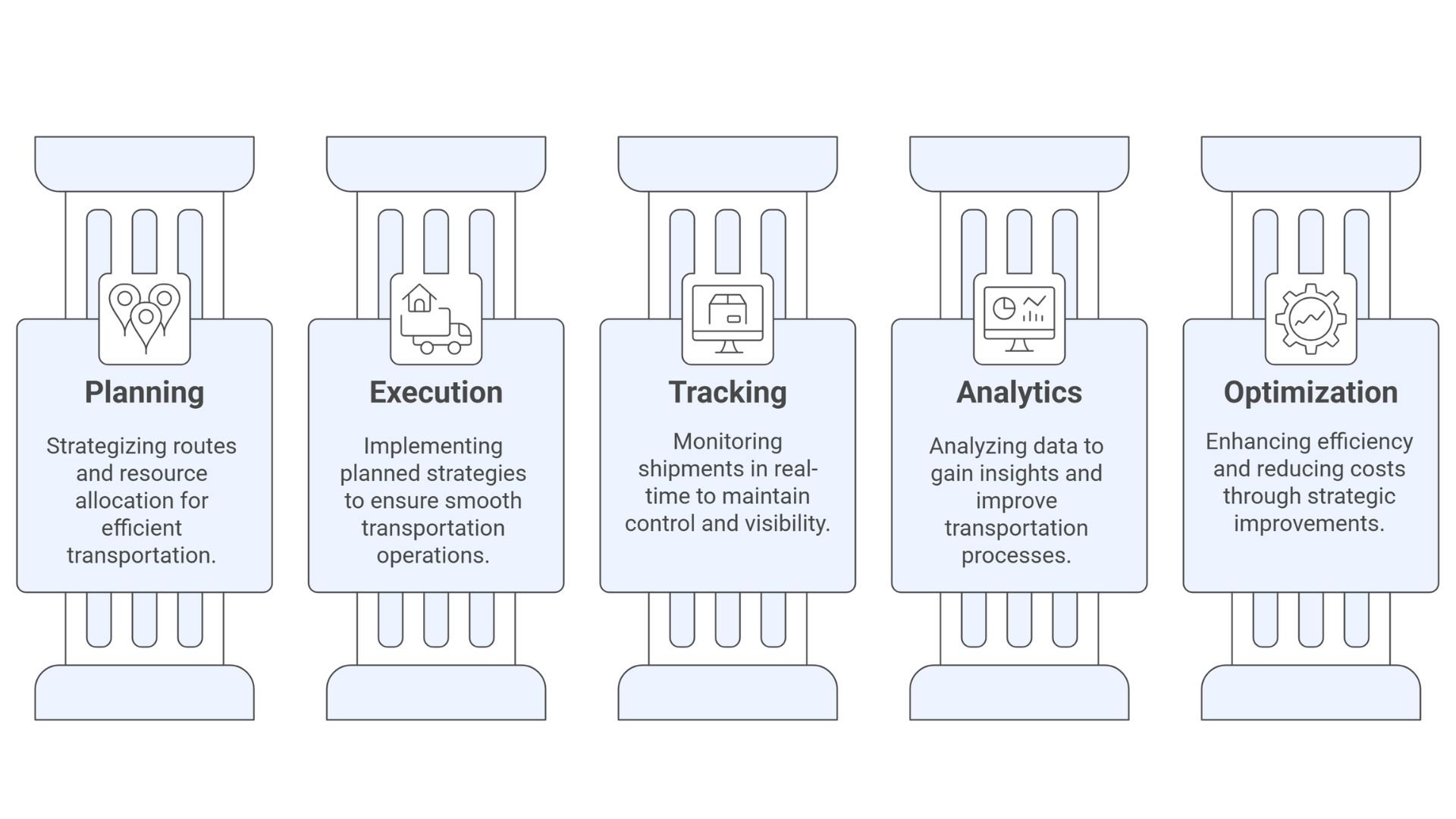

Core Functions: A 5-Pillar System of TMS

For robust, efficient shipping, a Transport Management System operates through five steps. These are:

- Planning: Based on the performance of B2B logistics service providers, TM System picks the right carriers and routes. It then schedules pickups and drop-offs and provides comparable shipping rates across the listed logistic companies.

- Execution: Once a logistics company is finalized, it books shipments with carriers and creates pickup requests. Meanwhile, it also generates the necessary shipping paperwork.

- Tracking: Shows live locations of goods, and alerts you if something's running late while keeping the end customer in the loop.

- Analytics: It breaks down shipping costs and delivery times and generates a final report of each order. It also highlights where you can save money for similar deliveries in future.

- Optimization: Continue refining the processes by finding the cheapest shipping options, planning routes, and combining B2B shipments to cut costs.

This cycle continues over and over, and with each delivery, TMS evolves with new analytics and performance reports to make better decisions for future shipments.

Where TMS Fits Inside The Supply Chain Tech Stack

Why Transport Management Systems Are Essential In Modern Logistics (Key Benefits)

TMS software is a must for surviving in today's logistics game. Here are some key benefits of the TMS system:

1. Managing Complex Operations

Logistics has evolved to a complex system serving different transportation modes and routes. Without proper sorting and management software, all systems will bottleneck, and coordinating everything will become a nightmare.

2. Meeting Customer Demands

About 40% of customers want their deliveries to be faster. These faster deliveries usually cost more than standard delivery. So, a TMS gives businesses the ability to choose the best logistics partners based on each customer's requirements.

3. Getting Real-Time Visibility

Everyone, whether a supply chain manager or an end customer, wants to know where their current shipment is. Here, TMS tracks the shipment's live status and flags any delay.

4. Cutting Transportation Costs

TMS helps you to find the cheapest routes and best carriers for different types of your packages. It is proven that it can save 15%-20% of transportation charges.

5. Handling eCommerce Growth

Because TMS automates delivery routes and handles returns, e-commerce can now deliver millions of packages efficiently.

6. Reducing Manual Errors

Manual planning can lead to mistakes and delays. This is also true for managing transportation manually. A TMS not only selects carriers based on analytical data but also reduces decision-making time.

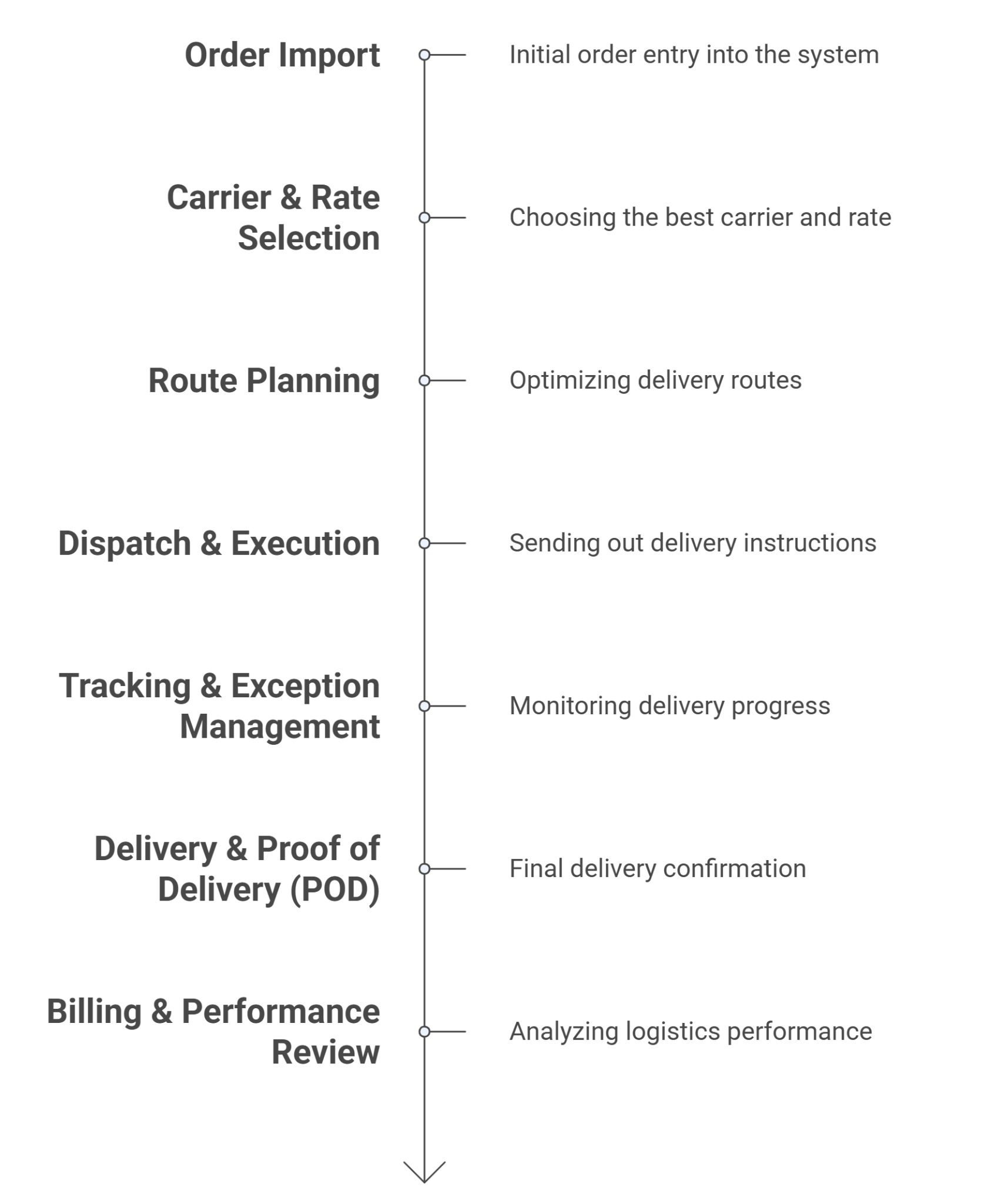

How A TMS Works: Step-By-Step Workflow

The following is the step-by-step procedure on how a Transport Management System (TMS) actually works:

1. Order Import

Once the customer places an order on the e-commerce site, a TMS retrieves the order from the Enterprise Resource Planning (ERP) system, along with the correct addresses, weights, and possible delivery dates.

2. Carrier & Rate Selection

Based on destination pin code, weights, and expected delivery date, a TMS checks out (in real-time) rates and sorts all carriers based on requirements.

Example: for faster delivery, a TMS system chooses air freight instead of truck. Some variables a company can choose are speed and price.

3. Route Planning

The system figures out the best routes using past analytic data and algorithms and predicts considerable traffic, delivery windows, and how drivers should move from one point to another.

4. Dispatch & Execution

Once TMS assigns each order to a carrier based on the requirements, it handles all the paperwork. It also notifies e-commerce and customers about the current shipment status. Drivers also receive updates on the routes they follow to delivery points (in case of PTL).

5. Tracking & Exception Management

The whole system keeps an eye on every dispatched shipment in real-time, along with GPS data. They mostly share updates to ecommerce/businesses and customers when the packages reach a hub or final delivery point.

6. Delivery & Proof of Delivery (POD)

Customers are notified when the package is "out for delivery." Once the package is delivered, drivers snap a photo or grab a signature as a delivery confirmation.

7. Billing & Performance Review

Final charges, along with freight bills, taxes, and overcharges, are added in TMS reports, which are finally used to generate carrier performance reports. With this data, a TMS can make smarter decisions going forward.

Key Features of Modern Transport Management System (TMS)

Modern TMS platforms are equipped with key features that make logistics smoother and essential. These reasons are:

- Route Optimization & Intelligent Planning: While compiling previous performance reports, a TMS system can find the best delivery routes and save fuel and transportation costs.

- Real-Time Shipment Tracking: With multiple tracking points and GPS data, a modern TMS can track the vehicle's current status and reduce possible delays.

- Documentation Automation: No manual work required. Here, systems automatically generate e-bills and invoices and share them with carriers. Moreover, it also takes care of GST forms that are manually filled by Indian truckers.

- Freight Rate Management: TMS provides a platform that gives you the choice to pick a carrier based on their prices and expected delivery times.

- Carrier Selection & Load Tendering: Software also sorts the carriers based on your shipping loads and matches them with available trucks. It also sends booking requests to preferred carriers and notifies the successful order.

- Performance Analytics & Reporting: It provides a comparison chart to compare each of the carriers' performance, delivery speed, successful delivery %, and expected delivery rates.

- Integration Capabilities: A modern TMS system can link up with multiple nodes in the logistics supply chain. It connects e-commerce, warehouse systems, and transportation services into a single system, enabling smooth data flow.

That's all about the Transport Management System (TMS) and how it has become an indispensable part of modern logistics, optimizing delivery routes according to delivery zone and slashing transportation costs.

We, at AAJ Supply Logistics, use the same advanced TMS system. You can also contact us today for a quote and streamline your shipments.